Depuis sa fondation en 1989, Crofter's Food Ltd produit des tartinades de fruits, confitures, gelées et conserves biologiques qui se démarquent de la concurrence. Avec un respect pour l'environnement et les principes biologiques, l'entreprise adopte des pratiques innovantes qui augmentent la durabilité et la saveur fruitée de leurs tartinades.

De plus, Crofter’s est très orientée vers la communauté. L'entreprise soutient financièrement la préservation des forêts, la Réserve de biosphère de la Baie Georgienne de l'UNESCO et le nettoyage de la Baie Georgienne sur le lac Huron.

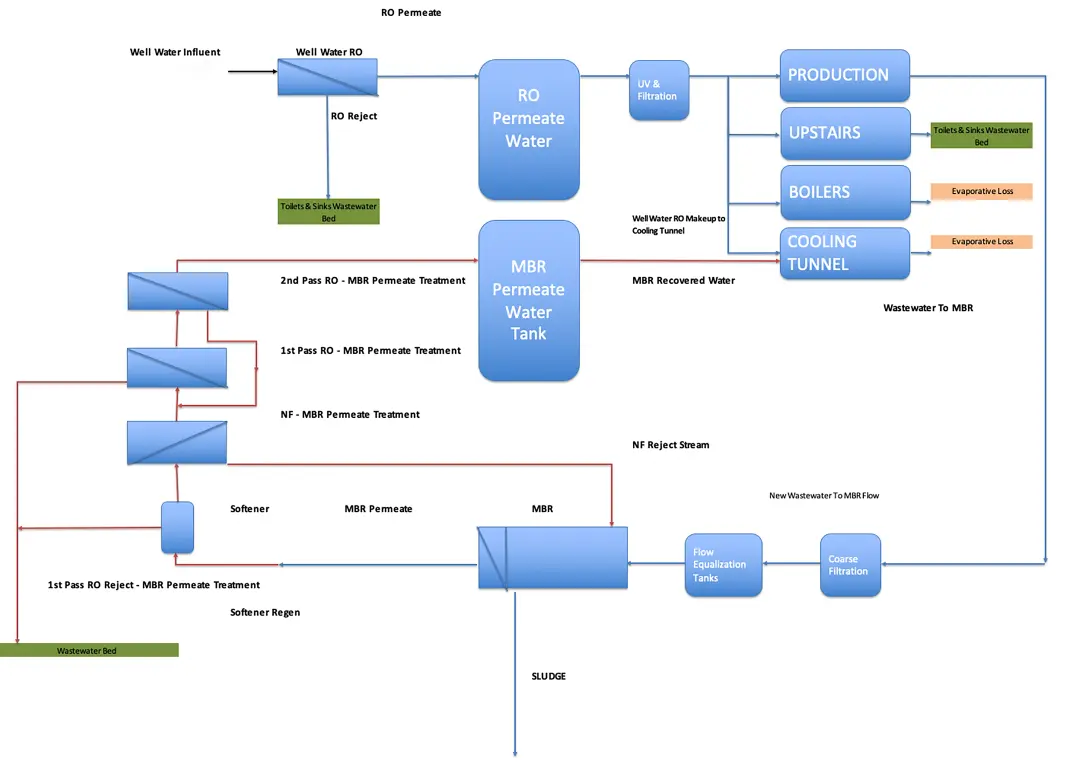

En 2015, Crofter’s a étendu ses installations à un nouveau site en dehors des services municipaux. Avec l'environnement à l'esprit et pour protéger leurs puits, ils ont construit un bioréacteur à membrane (MBR). Le MBR traite les eaux usées pour les réutiliser dans l'installation. En 2018, Crofter’s a encore investi pour réduire drastiquement la consommation d'eau. Ils ont mis à niveau leurs systèmes pour mieux réutiliser les eaux usées. L'entreprise faisait face à deux défis : gérer la consommation des puits et gérer les eaux usées rejetées dans un lit de traitement des eaux usées. Pour atteindre ses objectifs, l'entreprise voulait utiliser les eaux usées dans son tunnel de refroidissement de pasteurisation. Pour ce faire, les eaux usées traitées par le MBR devaient subir un traitement supplémentaire.

Pour atteindre ces objectifs, un partenariat Crofter’s / Durpro est né. Étant donné que la quantité et la qualité des eaux usées utilisées par Crofter’s étaient uniques pour ce type d'application, la solution proposée par Durpro était tout aussi unique.

Crofter’s a opté pour un système complet de traitement de l'eau/traitement des eaux usées et de gestion de l'eau basé sur ce schéma.

Grâce au système de récupération des eaux usées conçu par Durpro, Crofter’s a pu atteindre et même surpasser ses objectifs en termes de volume et de qualité de l'eau récupérée.

Pour en savoir plus sur le partenariat Crofter's / Durpro, remplissez ce formulaire.

Vous trouverez des détails sur les technologies, les techniques et les quantités d'eau et de contaminants traités.

Système de filtration à haut débit

Présentation d'un système de filtration équipé de trois membranes Hi-Flow de Suez. Offrant un débit de filtration allant jusqu'à 900 litres par minute et éliminant les contaminants de plus de 5 microns.