Purification de haute précision

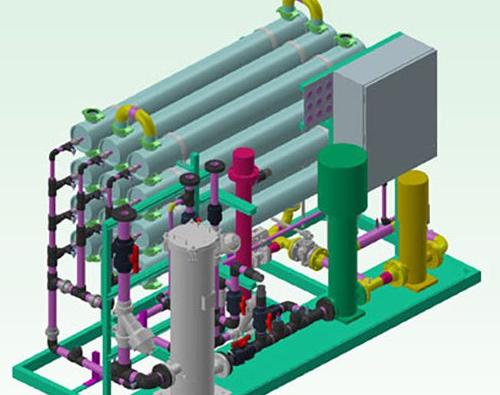

Le projet comportait des défis d'ingénierie en termes de fiabilité. La conception du système devait garantir une recirculation interne constante et prendre en compte les exigences spécifiques de l'environnement pharmaceutique hautement réglementé. Les procédures opérationnelles standard du client exigent le respect des bonnes pratiques de fabrication et la validation constante des processus et des composants.

Durpro a assuré une surveillance très rapprochée et a fourni au client toute la documentation nécessaire concernant la fiabilité et la qualité pour la multitude de tests effectués. La stabilité des processus et le contrôle bactérien sont essentiels en matière de filtration et de purification de l'eau dans l'industrie pharmaceutique. La pureté, les niveaux de chlore, le drainage, les vitesses — tout doit être minutieusement contrôlé.

Des solutions pour la vraie vie

Nos experts s'assurent toujours de bien comprendre comment nos solutions seront utilisées. Dans ce cas, il était primordial que le système soit facilement accessible et pratique à utiliser et à entretenir. C'est pourquoi nous avons travaillé en étroite collaboration avec le client pour revoir et configurer la disposition et les contrôles tout au long du processus. Tous les travaux nécessaires, y compris les arrêts, les démarrages et les reconnexions, peuvent facilement être effectués par les plombiers internes du client grâce à la disposition pratique du système et à la fonctionnalité de déconnexion rapide. Nous nous efforçons d'atteindre les normes les plus élevées, y compris l'efficacité et la facilité de maintenance !

Une équation qui se veut optimale

Notre équipe multidisciplinaire d'experts en filtration, purification et traitement de l'eau se concentre toujours sur vos besoins spécifiques. Nos solutions sont adaptées à vos défis, tâches et applications. Nous voulons que les systèmes que nous fournissons soient de qualité et de fonctionnalité optimales… et vous permettent d'économiser du temps, des efforts et de l'argent.

Nos solutions personnalisées sont soigneusement ciblées et parfaitement adaptées — ni plus ni moins. Il en va de même pour notre niveau d'intégration ; nous pouvons simplement soutenir la mise en service ou vous accompagner dès les premières étapes et tout au long du processus. Notre flexibilité et notre capacité à nous adapter à vos besoins sont des valeurs ajoutées importantes car pour vous, cela signifie un coût total de mise en œuvre et d'exploitation optimisé.